- Ideal for the defect cutting wood mouldings, wood flooring, finger joint blocks, wood paneling and more!

- Machine scans for defects marked with a florescent crayon allowing for high-speed defecting

- Provides 3 to 5 times higher production rate than manual cut-off saws.

- 5% increase in material yield over manual cutting operations

- +/- 1mm (0.0393”) accuracy

- Safe operation with automatic feeding and comprehensive safety guards

- Partial optimization with sequential and fixed part cutting functions or simply cut out defects

KEY ADVANTAGES

- User friendly touch screen control with on board synoptics, cutting counter, and menu based cutting modes

- Servo driven feed motor for fast accurate motion and position control

- Compact design requires less space than manual cutting setups

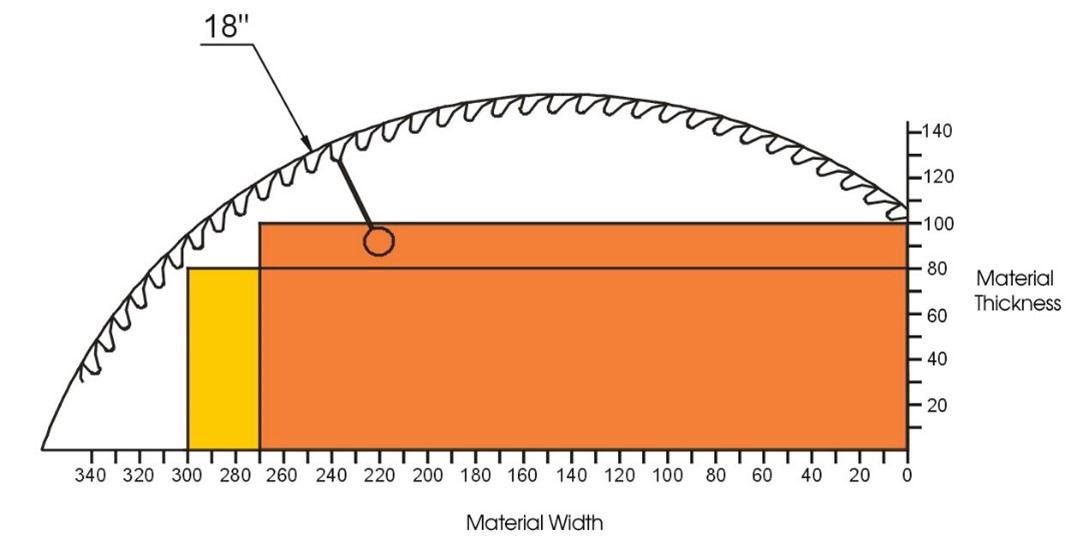

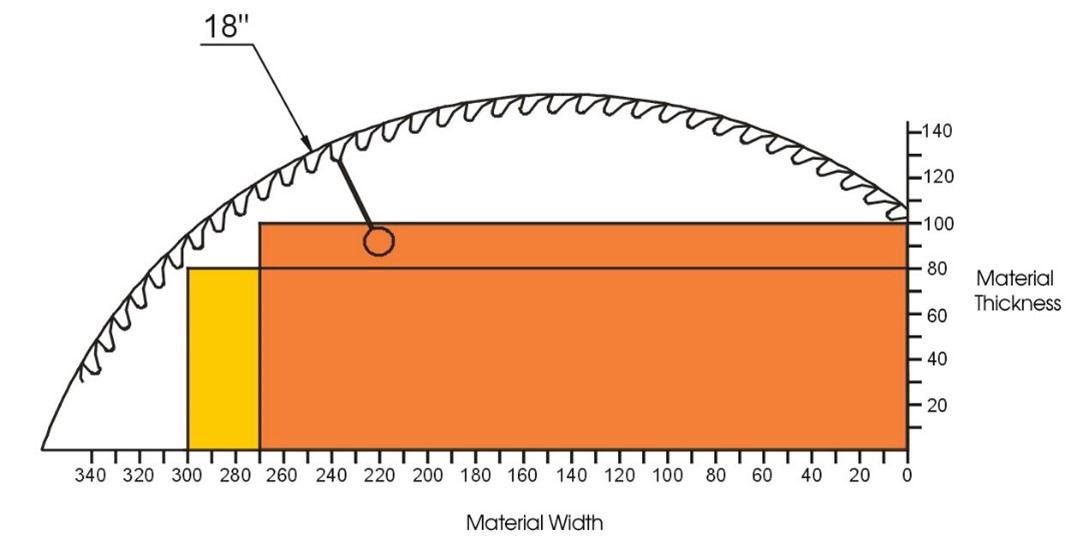

- 18” diameter blade provides a large cross cutting capacity

- Powerful 10HP motor running at 3200PRM

- Adjustable automatic trim of front and tail of the workpiece

- 48″ (1.2 meter) long infeed table (Longer available on request)

- 40″ (1 meter) long flat outfeed table

- Defect blowing system combined with computerized logic control permits the blowing time and the length of defect to be set as desired

SPECIFICATIONS

Saw Motor

|

10HP

|

Saw Spindle Speed

|

3200 RPM

|

Feed Motor (Servo motor)

|

2.7HP (2Kw)

|

Max. feed speed

|

Variable to 262 ft/min (80 m/min)

|

Max. infeed weight

|

44 lbs (20 kgs)

|

Circular Saw Diameter

|

Ø 18” (455mm)

|

Saw spindle diameter

|

30mm

|

Minimum distance between marks

|

0.787” (20mm)

|

Cutting Size – maximum

|

See the diagram of cutting range

|

Air pressure: for machine

|

72~85 PSI (5~6 kg/cm2)

|

Air pressure: defect blowing system

|

7~9 kg/cm2 (99.5~128 PSI)

|

Dust ports

|

2 @ 4”

|

Electrics

|

460/3/60 = 14 Full Load amps (Stock Machine)

|

Electrics

|

230/3/60 = 28 Full Load amps (Factory order)

|

Electrics

|

575/3/60 = 11 Full Load amps (Factory order)

|

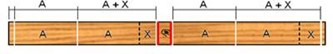

CUTTING MODES

FIX LENGTH CUTTING MODE

SEQUENTIAL CUTTING MODE

*10 sets of cutting size memory (for sequential cutting mode only)

MARKING LINES CUTTING WITH DOUBLE END TRIMMING

MARKING LINES (DEFECTS) CUTTING MODE AND FIXED LENGTH CUTTING MODE

THIS FUNCTION CAN DO THE FOLLOWING JOBS SIMULTANEOUSLY:

- Defect.

- Cut the fixed size (A).

- Cut Finger jointing size without lost (A+X).

CUTTING RANGE

Max. Cutting Range (WxH) – 11.8” x 2.75” (300x70mm) OR 5.9” x 3.9” (150x100mm) with 18” Blade – Inches = mm x .03937)

Min. Thickness = 0.4” (10mm) (Optional Thin Hold Down Device available to min thickness .078” (2mm)

- Thin Hold Down Device available to min thickness .078″ (2mm)

- Extended infeed table w/ rollers

- Powered infeed conveyor with inspection marking plate

- Lateral infeed chain for automatic loading